- This topic is empty.

-

AuthorPosts

-

15/12/2025 at 14:09 #9548

Elevator traction systems are widely used in commercial buildings, high-rise towers, hotels, residential complexes, and large public facilities because of their stability, energy efficiency, and high-speed performance. Despite their reliability, traction elevators are complex machines composed of motors, belts or wire ropes, brakes, control systems, sheaves, bearings, and multiple safety devices. With years of operation—especially under high load and intensive passenger flow—these systems inevitably face wear, mechanical stress, and electrical issues.

Understanding the common failures in elevator traction systems and knowing how to fix them is essential for building managers, maintenance teams, construction engineers, and elevator service providers. Addressing problems early improves safety, reduces downtime, and extends the overall lifespan of the equipment.

This article provides a comprehensive analysis of the most frequent failures in traction elevators, including symptoms, causes, troubleshooting steps, and recommended repair or prevention methods.

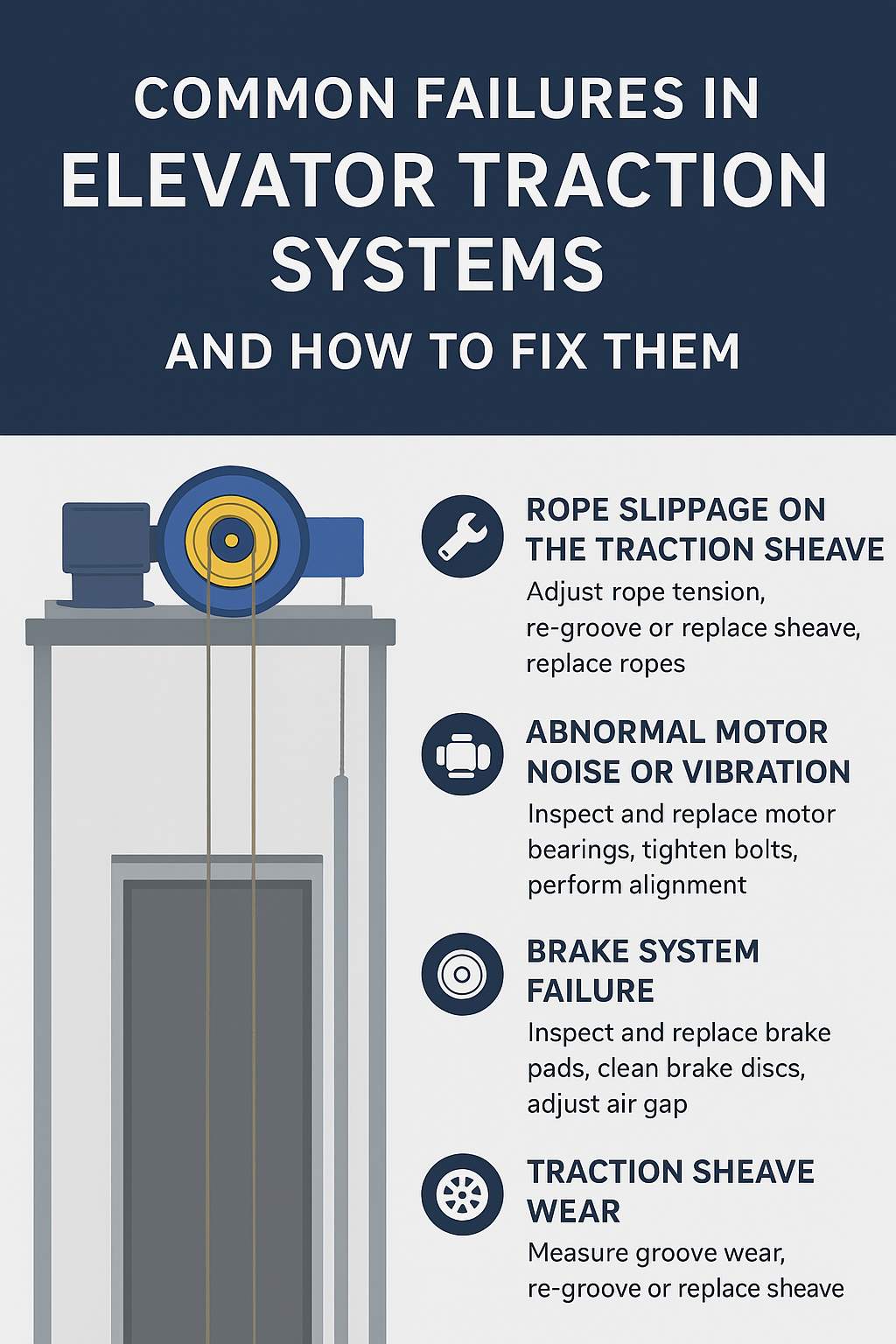

1. Rope Slippage on the Traction Sheave

Symptoms

-

Jerky or unstable elevator movement

-

Slower-than-normal acceleration

-

Car does not stop precisely at floors

-

“Sliding” sensation when starting or stopping

Causes

-

Worn traction sheave grooves

-

Over-polished or worn steel wire ropes / belts

-

Improper rope tension

-

Excessive lubrication on the ropes

-

Overloaded car causing imbalance

How to Fix It

1. Inspect rope tension:

Adjust all ropes to proper tension levels. Uneven tension among ropes is a common cause of slippage.2. Re-groove or replace the traction sheave:

If grooves are worn smooth or out of profile, traction efficiency drops significantly.3. Replace worn ropes or belts:

Ropes with excessive wear, corrosion, or diameter reduction must be replaced immediately.4. Remove excess rope lubrication:

Clean and re-lubricate according to manufacturer’s guidelines.5. Check counterweight balance:

Overloaded or improperly balanced systems affect traction quality.Prevention

-

Perform rope tension testing every 3–6 months

-

Use high-quality lubricants and follow standard lubrication cycles

-

Inspect sheave groove wear during annual maintenance

2. Abnormal Motor Noise or Vibration

Symptoms

-

Loud humming, grinding, or rattling noises

-

Motor overheating

-

Vibration felt in machine room or elevator shaft

-

Reduced ride comfort

Causes

-

Bearing wear or failure

-

Loose mounting bolts

-

Misaligned motor shaft

-

Motor winding issues

-

Unbalanced traction sheave

How to Fix It

1. Check and replace motor bearings:

Worn bearings are the most common source of noise and vibration.2. Tighten traction machine mounting bolts:

Looseness can cause resonance and instability.3. Perform shaft alignment correction:

Using laser alignment tools ensures precise calibration.4. Inspect winding resistance:

If windings are deteriorated, rewinding or full motor replacement may be required.5. Balance the traction sheave:

Unbalanced sheaves should be rebalanced or replaced.Prevention

-

Regular vibration analysis using condition-monitoring equipment

-

Maintain proper lubrication

-

Ensure correct installation and alignment during new elevator setup

3. Brake System Failure

The brake is one of the most important safety components in traction systems. Brake failure can cause uncontrolled car movement—one of the most dangerous elevator scenarios.

Symptoms

-

Car stops roughly

-

Car slowly slides when parked at a floor (“creeping”)

-

Abnormal squeaking or burning smell

-

Delayed brake release

Causes

-

Coil failure

-

Damaged or worn brake linings

-

Weak or broken brake springs

-

Dirt or oil contamination on brake surfaces

-

Incorrect air gap adjustment

How to Fix It

1. Inspect and replace brake pads:

Pads must maintain sufficient friction to stop the car reliably.2. Clean brake discs:

Remove dust, oil, and debris to ensure proper friction.3. Adjust air gap:

Incorrect air gap can cause late release or ineffective braking.4. Replace weakened brake springs:

Springs are critical to maintaining proper braking force.5. Test coil resistance:

Faulty coils should be replaced immediately.Prevention

-

Perform monthly brake tests and manual release checks

-

Replace linings before reaching wear limits

-

Keep the motor and machine room clean to prevent contamination

4. Traction Sheave Wear

Symptoms

-

Rope slippage

-

Irregular vibration

-

Reduced traction efficiency

-

Ropes wearing faster than normal

Causes

-

Years of continuous operation

-

Improper rope lubrication

-

Incorrect rope–sheave compatibility

-

Misalignment of ropes

How to Fix It

1. Measure groove wear:

If groove depth or profile deviates beyond standard, re-grooving is required.2. Re-groove the sheave:

Only certified technicians should perform this operation.3. Replace the sheave:

If re-grooving is no longer possible, the entire sheave must be replaced.Prevention

-

Monitor groove profile annually

-

Match rope diameter to sheave specifications

-

Use high-quality wire ropes or flat belts

5. Wire Rope or Belt Damage

Symptoms

-

Visible fraying

-

Flattened rope sections

-

Uneven tension

-

Unusual noise during car movement

Causes

-

Overloading

-

Poor lubrication

-

Incorrect sheave groove diameter

-

Corrosion due to humidity

-

Ropes rubbing against unintended surfaces

How to Fix It

1. Replace the ropes or belts immediately:

Damaged ropes pose severe safety risks.2. Correct tension across all ropes:

Uneven tension accelerates wear.3. Fix alignment issues:

Misaligned sheaves cause side-to-side rope wear.Prevention

-

Maintain controlled humidity in machine rooms and shafts

-

Follow rope inspection protocols every 3 months

-

Use manufacturer-approved ropes only

6. Control System Malfunctions

Symptoms

-

Elevator stops between floors

-

Unresponsive buttons

-

Error codes displayed on the controller

-

Car moves unexpectedly or fails to level properly

Causes

-

Faulty sensors (position, door, overspeed)

-

PCB board failures

-

Loose wiring connections

-

Software malfunction

-

Interference in signal transmission

How to Fix It

1. Check controller error logs:

Logs provide precise failure data for troubleshooting.2. Inspect wirings and connectors:

Loose connectors cause intermittent malfunctions.3. Replace defective sensors:

Leveling, hall call, door, or speed sensors often cause logic failures.4. Update the control software:

Some issues are solved with firmware patches.5. Replace damaged PCBs:

Elevator control boards should only be handled by certified technicians.Prevention

-

Perform regular software updates

-

Keep control panel clean and moisture-free

-

Conduct wiring inspections during routine maintenance

7. Excessive Heat in Traction Machine or Control Cabinet

Symptoms

-

Motor overheating alarms

-

VVVF inverter trips

-

Slow speed or reduced power

-

Burning smell from cabinet

Causes

-

Poor ventilation in machine room

-

Blocked cooling fans

-

Overloaded motor

-

Excessive friction in mechanical components

-

Faulty thermal sensors

How to Fix It

1. Improve ventilation:

Add cooling fans, air ducts, or temperature controls.2. Replace damaged cooling components:

Fans, filters, and thermal modules should function properly.3. Reduce motor loading:

Check for excessive counterweight imbalance or rope tension.4. Perform thermal scan:

Infrared scanning can pinpoint overheating components.Prevention

-

Keep machine rooms free of dust

-

Maintain proper ambient temperature (usually 5–40°C)

-

Test inverter cooling systems regularly

8. Car Leveling Issues

Improper leveling affects passenger comfort and safety.

Symptoms

-

Car stops slightly above or below floor level

-

Passengers trip when entering or exiting

-

Leveling error alarms appear

Causes

-

Encoder malfunction

-

Worn motor components

-

Rope stretch

-

Control logic issues

-

Brake problems

How to Fix It

1. Recalibrate or replace the encoder:

Incorrect position feedback disrupts leveling accuracy.2. Adjust rope tension:

Uneven or loosened ropes cause inconsistent leveling.3. Check brake performance:

Slipping brakes lead to leveling drift.4. Update leveling parameters in the controller:

Re-tuning improves accuracy.Prevention

-

Periodic rope shortening (when stretch exceeds limits)

-

Keep encoder free from dust

-

Perform leveling tests during maintenance

9. Unusual Cabin Noise

Symptoms

-

Clicking, rattling, or banging sounds during travel

-

Rubbing noises

-

Interior vibrations

Causes

-

Loose interior panels

-

Guide shoe wear

-

Debris on guide rails

-

Misalignment of cabin frame

-

Door track issues

How to Fix It

-

Tighten interior fixtures

-

Replace or lubricate guide shoes

-

Clean guide rails

-

Adjust door tracks and rollers

Prevention

-

Lubricate rail systems as scheduled

-

Conduct cabin interior inspections monthly

10. Counterweight Problems

Symptoms

-

Excessive vibration

-

Rope noise

-

Poor leveling and speed issues

Causes

-

Loose counterweight blocks

-

Misaligned guide rails

-

Incorrect counterweight ratio

How to Fix It

-

Re-secure all blocks

-

Align guide rails

-

Recalculate and adjust counterweight mass

Prevention

-

Inspect counterweight connections during annual checks

-

Monitor rope wear for signs of imbalance

Conclusion

Elevator traction systems are highly reliable and designed for decades of operation, but like any mechanical and electrical system, they are vulnerable to wear, environmental factors, and improper maintenance. Understanding common failures—such as rope slippage, motor vibration, brake malfunction, sheave wear, controller errors, and overheating—allows building operators and maintenance teams to identify early signs of trouble and take corrective measures before they escalate into major safety hazards.

Implementing preventive maintenance—including routine rope tension checks, brake adjustment, thermal monitoring, software updates, and environmental control—significantly reduces downtime and enhances elevator safety, comfort, and operational efficiency.

By combining early detection with professional repair practices, commercial buildings and high-rise structures can maintain stable, smooth, and energy-efficient vertical transportation for years to come.

As a professional elevator traction system supplier, Xinlin provides high-performance, reliable, and precision-engineered solutions designed for modern commercial and high-rise buildings. With deep expertise in traction technology, Xinlin focuses on delivering systems that ensure smooth operation, superior safety, and long service life. Our products undergo strict quality control, advanced testing, and continuous optimization to minimize common failures such as rope slippage, brake issues, sheave wear, and motor vibration. By combining robust mechanical design with intelligent control technology, Xinlin helps building owners, contractors, and elevator service companies achieve stable, efficient, and low-maintenance vertical transportation.http://www.xinlinelevator.com

xinlinelevator -

-

AuthorPosts

- You must be logged in to reply to this topic.