- This topic is empty.

-

AuthorPosts

-

15/12/2025 at 11:47 #9545

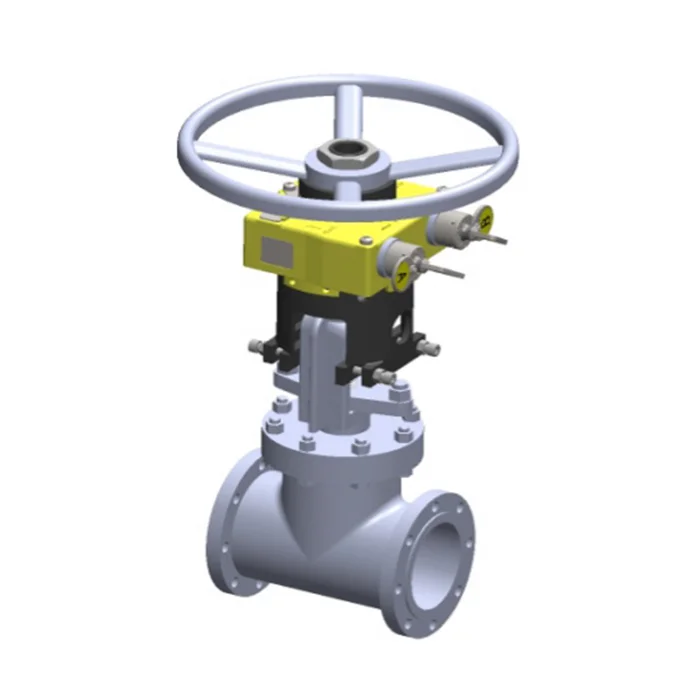

Mechanical valve interlock devices are critical safety components used to ensure proper sequencing and isolation of industrial valves. They prevent operational errors, enhance plant safety, and reduce the risk of accidents in industrial processes. While these devices are widely implemented in modern facilities, installing them in aging or legacy industrial plants presents unique challenges. Aging facilities often feature outdated infrastructure, worn-out piping, and non-standardized valve types, which can complicate installation and operation of valve interlocks. This article provides a detailed overview of precautions and best practices for installing mechanical valve interlock devices in aging facilities.

1. Understanding the Challenges of Aging Facilities

Before installation, it is essential to understand the challenges posed by aging facilities:

Outdated Valve Designs: Older valves may not conform to current standards, making it difficult to fit standard interlock devices.

Corrosion and Wear: Piping and valve surfaces may be corroded or worn, affecting the alignment and secure attachment of interlocks.

Non-standard Dimensions: Legacy plants often feature non-standard valve stems, handwheels, or mounting points, requiring customized interlock solutions.

Limited Documentation: Drawings and records may be incomplete or outdated, complicating assessment of the valve network.

Space Constraints: Aging facilities may have tight or restricted spaces around valves, limiting access for installation and maintenance.

Recognizing these issues upfront is crucial to prevent costly mistakes during installation.

2. Conducting a Thorough Facility Survey

A detailed survey is the first step before installing mechanical valve interlocks:

Valve Assessment: Inspect all target valves for type, size, orientation, and condition. Identify any valves that may require refurbishment or replacement before interlock installation.

Pipe and Flange Inspection: Check for corrosion, deformation, or misalignment in the surrounding piping that could affect interlock performance.

Accessibility Evaluation: Ensure sufficient clearance for installation tools and routine maintenance. Plan for scaffolding or temporary support if needed.

Documentation Review: Collect and verify all available drawings, maintenance records, and operational manuals. Cross-check them with on-site observations.

A comprehensive survey minimizes surprises during installation and ensures proper selection of interlock devices.

3. Selecting Suitable Mechanical Valve Interlocks

Choosing the correct interlock device is critical in aging facilities:

Compatibility: Ensure the interlock is compatible with the specific valve type, size, and operation mode (manual, motor-operated, or gear-operated).

Material Selection: Use corrosion-resistant materials such as stainless steel or coated alloys for areas with high humidity or chemical exposure.

Custom Solutions: For non-standard valves or irregular mounting conditions, consider custom-designed interlock devices.

Safety Standards: Verify that the interlock meets applicable industry standards (API, OSHA, or ISO) for industrial safety and operational reliability.

Proper selection reduces the risk of operational failure and enhances the safety and longevity of the interlock system.

4. Pre-Installation Preparations

Effective preparation reduces complications during installation:

Valve Servicing: Clean, lubricate, and, if necessary, refurbish valves to ensure smooth operation. Replace damaged components before attaching interlocks.

Mock-Up Installation: For complex or tight installations, perform a trial assembly off-site or in a controlled area to identify potential issues.

Tool Readiness: Ensure that the correct tools, fasteners, and measurement equipment are available for the installation process.

Training Personnel: Technicians should be familiar with the interlock mechanism, installation procedures, and safety precautions.

Proper preparation improves installation efficiency and reduces the likelihood of post-installation failures.

5. Installation Precautions

When installing mechanical valve interlocks in aging facilities, adhere to the following precautions:

Secure Mounting: Ensure the interlock is firmly attached without putting excessive stress on the valve stem or surrounding piping. Loose or misaligned installations can lead to malfunction.

Alignment Verification: Confirm that the interlock mechanism aligns precisely with valve rotation or actuation requirements. Misalignment can cause binding or incomplete interlocking.

Avoid Modifications on Valve Components: Minimize drilling, welding, or structural modifications on existing valves to preserve their integrity. Where modifications are unavoidable, consult engineering experts.

Check Operational Clearance: Ensure sufficient space for valve operation, maintenance, and emergency intervention without interfering with the interlock.

Sequential Testing: Test the interlock system for proper sequencing and functionality under various operating scenarios before commissioning.

These precautions help maintain the reliability of the interlock system while safeguarding the aging infrastructure.

6. Post-Installation Testing and Validation

Testing and validation are critical to ensure safe and effective operation:

Functional Testing: Operate each valve through its full range of motion to confirm that the interlock functions correctly and prevents unauthorized operation.

Load and Torque Assessment: Verify that the interlock does not impose excessive torque on the valve stem or actuator, which could damage aging components.

Emergency Scenarios: Simulate emergency or shutdown scenarios to confirm that interlocks perform as intended under stress conditions.

Documentation: Record installation procedures, test results, and any modifications made for future maintenance and audits.

Rigorous testing ensures that the interlock system operates safely and reliably in the facility’s specific conditions.

7. Maintenance and Monitoring

Ongoing maintenance is crucial in aging facilities:

Routine Inspection: Regularly inspect interlock devices for wear, corrosion, and proper alignment.

Lubrication: Apply appropriate lubrication to moving parts to maintain smooth operation.

Adjustment and Calibration: Periodically adjust interlocks to compensate for wear or slight shifts in valve alignment over time.

Training and Awareness: Ensure operational staff are trained to understand the function and importance of mechanical valve interlocks.

Proactive maintenance prolongs the life of both the interlocks and the existing valve infrastructure.

8. Safety Considerations

Safety should remain the top priority:

Lockout/Tagout Integration: Integrate mechanical valve interlocks with lockout/tagout procedures for enhanced safety during maintenance.

Hazard Assessment: Identify potential hazards associated with aging valves, high-pressure lines, or chemical exposure before installation.

Emergency Access: Ensure interlocks do not obstruct emergency access or impede critical safety operations.

Compliance: Adhere to industry regulations and standards for valve interlocks, such as API, ISO, or OSHA guidelines.

A strong safety culture ensures that interlocks function as intended while minimizing risk to personnel and equipment.

9. Conclusion

Installing mechanical valve interlock devices in aging facilities is a challenging but essential task to improve operational safety and prevent human error. By carefully assessing the facility, selecting compatible interlocks, preparing the site, following installation precautions, and conducting thorough testing, industrial plants can successfully integrate these safety devices even in legacy infrastructure. Regular maintenance and safety awareness further ensure long-term reliability. With proper planning and execution, mechanical valve interlocks can significantly enhance safety, compliance, and operational efficiency, even in aging facilities with complex challenges.

Nudango, as a professional mechanical valve interlock system supplier, is committed to providing high-quality, safe, and reliable valve interlock equipment for various industrial facilities. Whether in new plants or existing facilities, we can provide customized solutions based on the specific site conditions, ensuring safe valve operation, reducing the risk of human error, and helping companies comply with international industrial safety standards.http://www.nudango.com

nudango -

AuthorPosts

- You must be logged in to reply to this topic.