- This topic is empty.

-

AuthorPosts

-

19/09/2025 at 18:08 #8742

https://www.magicmag-tech.com/the-innovative-application-of-magnetic-couplers.html

At the heart of industrial and mining operations, large pumps are critical assets. However, their traditional drive systems often come with inherent drawbacks such as low efficiency, high maintenance, and premature equipment failure. The advent of the Magnetic Coupler has ushered in a quiet revolution in this field, redefining the standard for driving large pumps with its non-contact transmission technology.

1. A Paradigm Shift in Principle: From Hard Connection to Soft Start

Unlike traditional couplings that rely on rigid mechanical connections, magnetic couplers transmit torque without physical contact through powerful magnetic fields generated by permanent magnets. The core structure consists of two halves: a copper conductor ring (rotor) connected to the motor and a permanent magnet rotor connected to the pump shaft. When the motor rotates, magnetic interaction across the air gap drives the pump impeller to rotate synchronously—no physical contact is needed.

2. Value of Innovative Application: Solving Four Major Pain Points

-

Energy Savings & Operational Efficiency:

Large pumps demand high inrush current during startup. Magnetic couplers enable perfect soft starts and soft stops, transmitting torque smoothly to significantly reduce motor starting current (often by over 30%) and minimize grid impact. Their speed regulation capability allows output to be flexibly adjusted based on actual conditions (e.g., flow rate, head pressure), avoiding the massive energy waste caused by throttle valves. Overall energy savings can reach 20-40%. -

Misalignment Tolerance, Reducing Installation & Maintenance Costs:

Precise alignment for large equipment is time-consuming and prone to change due to foundation settlement. Magnetic couplers accommodate significant radial, axial, and angular misalignment, entirely eliminating the vibration, noise, and bearing wear caused by misalignment. This drastically reduces installation time and significantly lowers long-term maintenance costs and downtime risks. -

Overload Protection, Safeguarding Equipment:

In overload situations like pump blockage or jamming, traditional couplings transmit torque rigidly, potentially burning out the motor or damaging the pump. Magnetic couplers provide inherent overload protection. If the load exceeds the set torque, the inner and outer rotors slip automatically, isolating shock and protecting both motor and pump from damage—acting as an essential "safety guard" for the system. -

Vibration Damping & Noise Reduction, Improving the Work Environment:

As a non-contact drive, magnetic couplers fundamentally eliminate vibration transmission paths. Their smooth operation markedly reduces vibration and noise throughout the drive system, not only extending the life of bearings and mechanical seals but also creating a better working environment for operators.

3. Broad Application Scenarios

This innovative technology delivers immense value across various large pump applications in industrial and mining settings:

-

Mine Dewatering and Mineral Processing Pumps: Handles harsh conditions, preventing equipment damage from jamming due to slurry and debris.

-

Power Plant Circulating Cooling Water Pumps: Enables efficient speed regulation to match cooling demand, offering notable energy savings.

-

Corrosive Media Transfer Pumps in Chemical and Metallurgical Industries: Requires no mechanical seal, achieving true zero leakage for enhanced safety and environmental protection.

-

Large Pump Stations in Municipal and Industrial Water Treatment Plants: Tolerates installation misalignment, reduces maintenance, and ensures continuous, stable operation.

The application of magnetic couplers on large pumps is far more than a simple component replacement; it represents a smarter, more reliable, and more energy-efficient systemic solution. It helps industrial and mining enterprises reduce operational costs at the source while enhancing equipment safety and reliability, making it a key innovative technology driving the transition towards efficient and green production in the industrial sector.

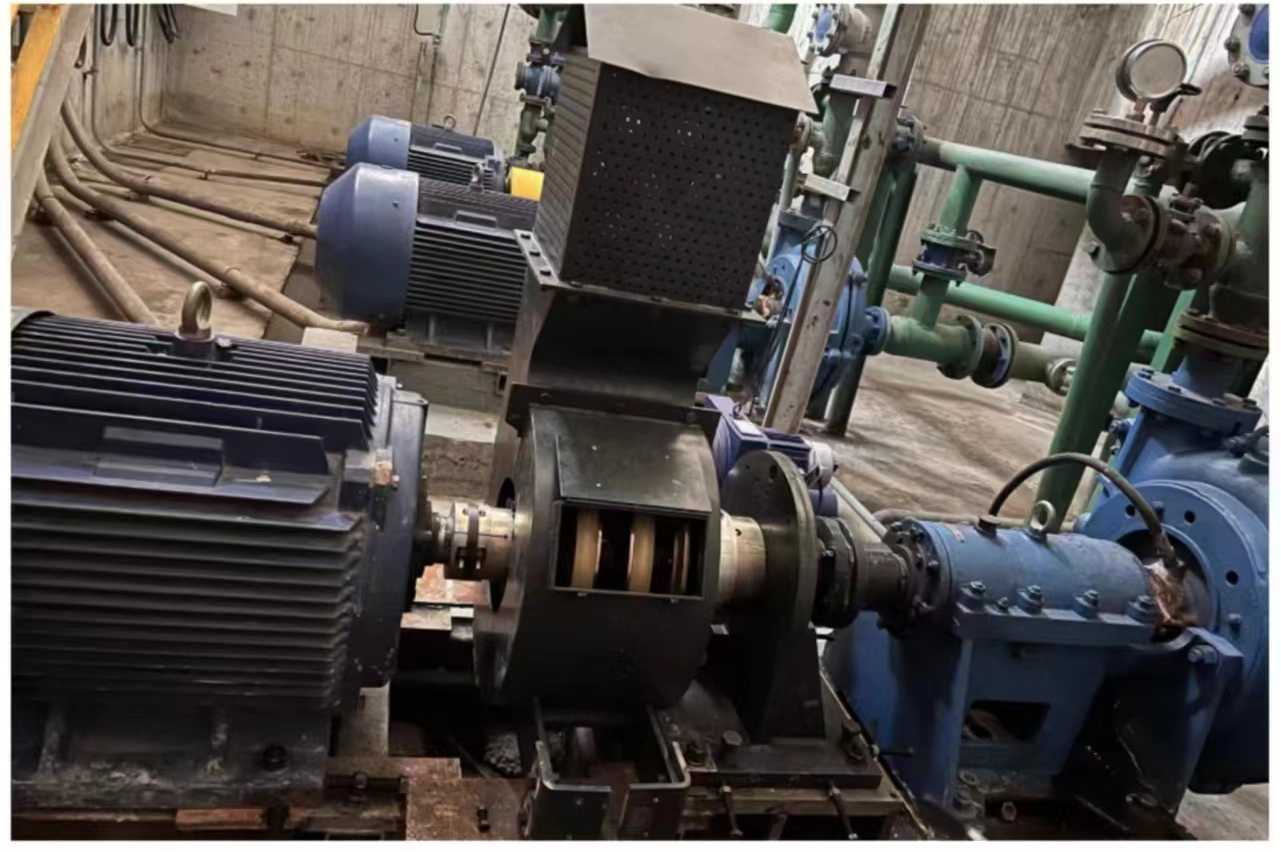

Application of MaginMAG FBM basic type magnetic coupling in coal mine water pump

Application of MaginMAG FBM basic type magnetic coupling in power plant water pump

Application of MaginMAG ASD speed-regulating type magnetic coupling on water pump in steel plant

https://www.magicmag-tech.com/the-innovative-application-of-magnetic-couplers.html

SHANGHAI GAOLV E&M Technology Co.,Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.