- This topic is empty.

-

AuthorPosts

-

24/12/2025 at 17:31 #9669

https://www.ascendtechs.com/guangzhou-ascend-liquid-injection-pumps.html

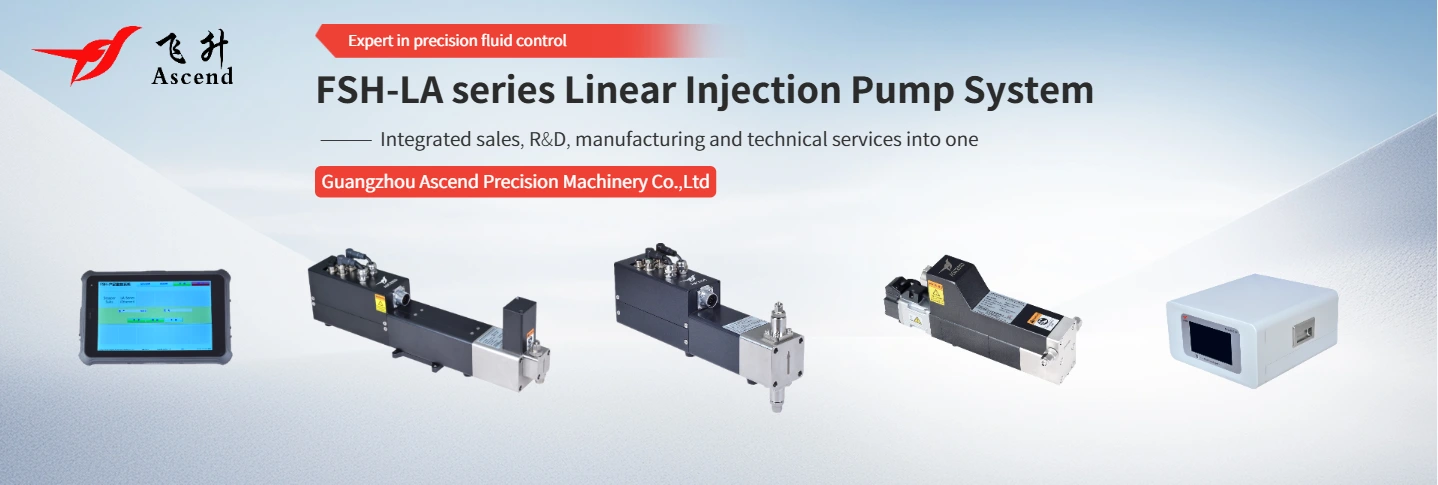

Against the backdrop of the accelerating global energy transition, sodium-ion batteries are emerging as a new favorite in the new energy sector, thanks to their advantages of abundant raw material resources, low cost and high safety. Equipped with its independently developed FSH-CF/LA series liquid injection pump systems, Guangzhou Ascend Precision Machinery Co., Ltd. injects core impetus into the mass production of sodium-ion batteries and propels China’s sodium-ion battery industry into a new stage of scale and intelligence.

Sodium-Ion Battery Boom: Breaking the Resource Dilemma & Cost Anxiety

Global sales of new energy vehicles have exceeded 30 million units, laying bare the acute supply-demand imbalance of lithium resources. With China’s lithium reserves accounting for a mere 6% of the global total and sodium reserves being 440 times that of lithium, such a resource disparity has positioned sodium-ion batteries as the key solution to addressing "lithium anxiety". In terms of cost, the pack cost of sodium-ion batteries will be 30% lower than that of lithium iron phosphate batteries in 2025. Meanwhile, continuous breakthroughs have been achieved in core performance metrics such as cycle life and rate capability, enabling sodium-ion batteries to replace lithium batteries in scenarios including energy storage and two-wheeled vehicles. At present, the sodium-ion battery production lines planned by CATL, Zhongke Haina, BYD and other enterprises are accelerating their implementation, marking the official entry of sodium-ion batteries into the stage of large-scale application.

Precision Injection: The "Cardiac Pumping" Project for Sodium-Ion Battery Mass Production

The mass production of sodium-ion batteries cannot be achieved without the support of high-precision liquid injection technology. As a core step in battery manufacturing, the liquid injection process directly impacts the consistency of battery capacity, cycle life and safety performance. FSH-CF series constant flow injection pump system & FSH-LA series linear injection pump system independently developed by Guangzhou Ascend deliver three core values for sodium-ion battery mass production:

1. Ultra-Precision Liquid Injection: Solving the Process Challenges of Sodium-Ion Batteries

The radius of sodium ions is 70% larger than that of lithium ions, which leads to a more complex pore structure of electrode materials and imposes more stringent requirements on liquid injection precision. The FSH-CF series adopts a servo-driven camshaft design and achieves a ±0.3% repeatability accuracy through micron-level machining technology, ensuring stable liquid injection volume per battery cell. Its pulse-free liquid injection characteristic eliminates liquid inertial impact, prevents electrolyte stratification and significantly enhances the cycle stability of batteries.

2. Full-Scenario Adaptability: Covering Diverse Forms of Sodium-Ion Batteries

For different packaging formats of sodium-ion batteries—including cylindrical, pouch and blade types—the FSH-LA series can also provide modular solutions. The FSH-LA linear liquid injection pump is highly compatible with the production of cylindrical batteries such as 14500, 18650 and 21700, and its integrated drive-control structure saves 30% of the installation space. Some models are ATEX-certified for explosion protection, meeting the production requirements of high-temperature systems such as sodium-sulfur batteries. The multi-pump coordinated control system can manage multiple liquid injection units simultaneously, helping to break the bottleneck of single-line production capacity.

3. Intelligent Management & Control: Building a Solid Line of Safety Defense

The flammable nature of sodium-ion battery electrolytes places higher safety requirements on production equipment. The explosion-proof pump head of the FSH-CF series is made of 316L stainless steel, featuring resistance to acid and alkali corrosion and stable operation in high-humidity and strong acid-alkali environments.

Technology Leadership: The Hard-Core Strength of Ascend Liquid Injection Pumps

Guangzhou Ascend Precision has specialized in the fluid control field for 12 years. Its liquid injection equipment has been serving leading enterprises including CATL, BYD, Envision, EVE Energy and others, and built three major technological barriers in the battery liquid injection sector.

● Material Compatibility: Special sealing technology is adopted to address the corrosion issue of sodium salt electrolytes on equipment, extending the average service life of equipment to over 5–8 years.

● Data Connectivity: Equipped with Ethernet communication interfaces, it can seamlessly connect to the MES system and achieve full-process traceability of liquid injection parameters.

Green Future: Synergistic Evolution of Sodium-Ion Batteries and Liquid Injection Pumps

As the energy density of sodium-ion batteries exceeds 200 Wh/kg, their application scenarios are expanding from energy storage and two-wheelers to A00-class electric vehicles and engineering machinery. With its technical philosophy of "millimeter-level precision, microsecond-level response and intelligent management & control", Guangzhou Ascend has been continuously providing core equipment support for the mass production of sodium-ion batteries, helping China achieve the leap from a follower to a leader in the global sodium-ion battery race.

https://www.ascendtechs.com/guangzhou-ascend-liquid-injection-pumps.html

Guangzhou Ascend Precision Machinery Co.,Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.